Technical features

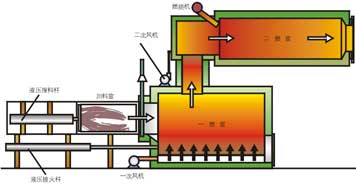

We set 2 combustion chambers to use pyrolytic incineration ways to dispose rubbish.

The system has high self-control and can incinerate rubbish completely.

During the process of incineration, the rubbish layer will not agitate and cause less fly ash emission.

The rubbish burns in first combustion chamber, which can benefit for metal recycle and avoid the dioxin mass production.

The second combustion chamber using 3T technology can reduce the production of dioxin pollution.

The requirement of burning rubbish

Water content<30%

Ash content<20%

Glass content<3%

Rubbish averaged heating value>10MJ/kg

Bulk density 80~120kg/m3

The combustion liquid waste can also be sprayed into the furnace to incinerate.

The technical process

The rubbish in dump pit will be put into additive bin of combustion chamber by grab bucket. The hydraulic system will open to push the rubbish of additive bin into first combustion chamber through the vertical door of material inlet. After ignition, the rubbish of first combustion chamber would pyrolysis under the temperature of 300~800℃. The combustible gas generated by pyrolysis will come into the second combustion chamber to burn completely. The temperature of second combustion chamber will be kept from 850 to 1200℃. That can keep enough time for gas to stay so that the combustible gas and some dioxin can be generated completely.

The high temperature gas discharged from the second combustion chamber will be recovered by the waste heat boiler. It will produce the steam and hot water to support living. And because of sudden cooling during this period, it avoids the dioxin resynthesis. After leaving waste boiler, the gas will be removed the pollutant such as HCI, SO2, heavy metals and dioxins and so on by the gas purification system. And finally, the gas will discharged into the atmosphere via the induced draft fan and chimney.

Technical information

- Last:Nothing

- Next:The Technology Introduction of Water Storage Air Conditioning